The science of adhesive, particularly in the context of making tapes stick, delves into the intricate interplay between various adhesive substances and the surfaces they are applied to.

Adhesives are designed to bond between two surfaces by forming molecular attractions with the surface molecules, essentially establishing a strong connection. Tapes are engineered with specific adhesive properties to cater to different applications, ranging from simple household tasks to complex industrial needs.

There are several types of tapes available, each tailored to meet different requirements:

- Pressure-Sensitive Tapes: These tapes feature adhesives activated by pressure, requiring no additional heat or solvents for bonding. They adhere well to various surfaces and are commonly used for packaging, labeling, and mounting tasks.

- Double-Sided Tapes: As the name suggests, these tapes have adhesive coatings on both sides, allowing them to bond two surfaces together. They are often used in crafting, construction, and mounting applications.

- Masking Tapes: These tapes are designed to be easily removable without leaving residue behind. They are commonly used in painting and crafting to mask off areas that should not be painted.

- Duct Tapes: Duct tapes are known for their strong adhesion and versatility. They are typically used for temporary repairs, bundling items, and sealing ductwork.

- Electrical Tapes: These tapes are specifically designed to insulate and protect electrical wires and components. They provide excellent resistance to heat, moisture, and chemicals.

- Specialty Tapes: Numerous specialty tapes are available for specific applications, such as medical tapes for wound care, automotive tapes for vehicle repairs, and reflective tapes for safety purposes.

Installing tapes typically involves a few basic steps:

- Surface Preparation: Ensure that the surfaces to be bonded are clean, dry, and free of any dust, oil, or debris that could interfere with adhesion.

- Application: Carefully apply the tape to the desired surface, using firm and even pressure to ensure proper contact between the adhesive and the surface.

- Bonding: Allow sufficient time for the adhesive to create a strong bond with the surface. In some cases, applying additional pressure or using heat may help enhance bonding.

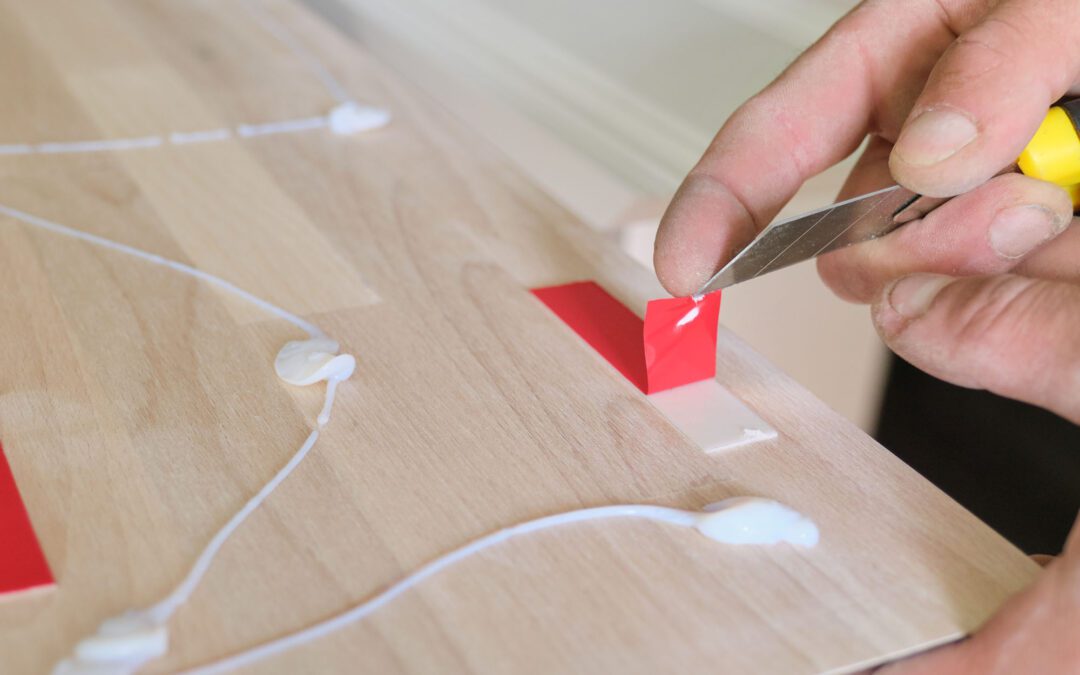

- Trimming: Trim any excess tape to achieve a neat finish.

By understanding the science behind adhesion and selecting the appropriate type of tape for the task, users can achieve reliable and long-lasting bonds in various applications.